In machining, productivity is defined as

the ratio between output and input. Machining input

includes the resources made available for production, i.e.

operator, machinery, equipment, workpiece material, toolroom

inventory and overhead. Output is basically what gets

done during the available production time.

Tool life

or

cutting data

|

=

Tool cost  =

Material cost  =

Machine cost  =

Personal cost  =

Factory cost

|

Modern cutting tools correctly applies and

with optimized cutting data have a major cost saving effect!

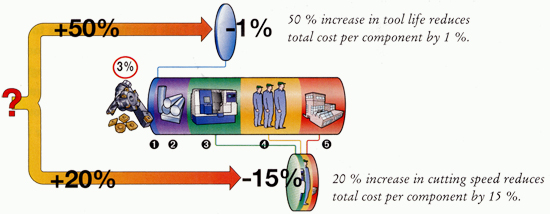

It is estimated that cutting tools represent

about three percent of the total production costs and will

most likely be decreased in the future as development of cutting

tool technology advances. Savings on most tool costs

will therefore only have a marginal effect and cannot compare

with the savings that can be achieved by lowering the production

costs through increased output.

By choosing high quality cutting tools and

increasing cutting data, considerable cost reductions can

be achieved.

A 20% increase in speed or feed

can equal a 15% cost reduction.

Improve performance and results. Your

Sandvik Coromant representative can help select the best tools

for your operation and show you how to apply those tools to

achieve cost savings.

|