Step #1

Analyze the sawing

application

Machine:

For most situations, knowing the blade dimensions (length

x width x thickness) is all that is necessary.

Material: Find out the following

characteristics of the material to be cut:

•

Grade

•

Shape

• Hardness

•

Size

•

Is the material to be stacked (bundled) or

cut one at a time?

Other

Customer Needs:

The specifics of the application should be considered.

• Production or utility/general purpose sawing operation?

• What is more important, fast cutting or tool life?

Step #2

Determine

the proper number of teeth per inch (TPI)

Use the Tooth Selection Chart on the right

A

general rule for bundles: Determine the correct

TPI for one piece and choose one pitch coarser for the bundle.

Step #3

Determine which blade type

to use

Refer to the Product Selection Charts on

the opposite page. Find the material type to be cut

in the top row. Read down the chart to find which

blade is recommended. For further assistance, contact

LENOX Technical Support at 800-642-0010.

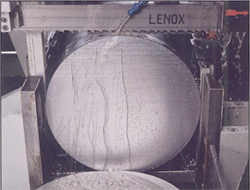

Step #4

Order

LENOX Sawing Fluids and Lubricants

... for

better performance and longer life on any blade.

|

Square/Rectangle

Solid

Locate width of cut (W)

|

Round Solid

Locate diameter (D)

|

Tubing/Pipe/Structurals

Locate wall thickness (T)

|

|

|

|

|

|